- DME Channel on YouTube

Since the founding of DME 1979, at this time a consulting company in the area of micro processing, a main strength of our company is the development of customer streamlined software solutions. Our new SPM Software "ScanTool™"" combines in itself the experience of decades of software design and SPM development. The main focus point for the design was highest efficiency through accelerated work-flow and user defined automation procedures. Intuitively organized control panels, full data and command access and multiple support functions guarantee maximum output for users off all experience levels. The open design also enables our programmers to implement customer specified functions as automated scanning procedures with report generation or operating interface for combined measurement systems.

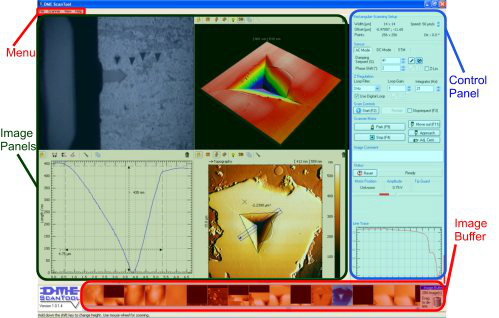

The ScanTool™ user interface was designed to meet highest standards in flexibility and work-flow. All relevant functions to operate the SPM are located on the User interface. More advanced image treatment or automation functions are not more than a "click" away. Intuitive operation of the SPM is supported by the division of the User interface in different sections of function:

- Image Panels: SPM Scans, light microscopy images, force distance curves can be displayed and edited. The number of panels can be varied.

- Control Panel: All major settings to operate the SPM can be accessed here.

- Image Buffer: Saved SPM scans and other images and curves can be stored, and reviewed here.

- Menue: Gains access to more advanced scanning and data logging functions.

Through this organized layout SPM novices are able to get used to the software and the operation of the SPM in a small amount of time. Experienced users will enjoy the direct access to the image data and the abilities to automate the system.

Our SPMs are developed to deliver high quality results in a minimum of time. The new ScanTool™ software represents another big step in this direction. Implemented functions support the user to reach his main goal, high resolution, artifact free, reliable results. These little helpers lead SPM novices on the way to high quality images and accelerate the learning curve. Experienced users will regard the support while conquering most complicated measuring and sample conditions. Additionally they enable to generate long time measuring routines characterizing a large number of sample areas. All these functions are selectable one by one and can be activated or turned off by the operator:

| TipGuard: The tip guard watches the tip-sample interaction and steps in if the get too high. This elongates lifetime and prevents artifacts in the SPM scan. |

| Intelligent Approach: Always reach the sample surface! No false approaches and ending up scanning without surface contact! Even on rough and charged samples or in liquid. |

| Amplitude control: Controls and corrects the AC cantilever oscillation if necessary. Enables long measurement routines with hundreds of scans and approaches. |

| Phase Align: Adjusts the phase for maximum signal to noise ratio in phase based measurement modes (phase imaging, MFM etc.). |

| Show area:The Cantilever tip outlines the area to be scanned. Enables fast alignment of scan field and area of interest |

In manual operation day long measuring sessions are necessary to generate the required data for statistical analysis.

Often such trivial activities like adjusting the position of the scan area on the sample require the presence of an operator.

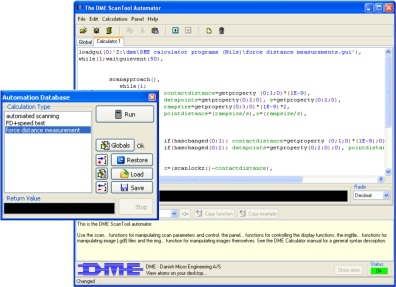

The build in "Automator" enables to generate basic and highly complex measurement routines. The "Automator"

gains direct access to all instrument and program functions via an easy to learn programming code, which bases on the

Calculator. The "Automator" enables unknown freedom in the design of experiment

specific SPM usage. These possibilities can be used either by the user himself or gives our software department the possibility

to generate user defined solutions. The possibility to generate GUI´s and the "Automation database" allows to

store, access and activate "Automator" programs without handling any line of program code.

The ability to generate and run customer and application dedicated measuring procedures enhances data acquisition to a high

level and supports in this way economic efficiency of the system.

For more information download our short ScanTool™ brochure.