- DME Channel on YouTube

Our instruments are characterized by the simplest possible operation combined with the capability of a high throughput. When it comes to new developments, we take great care to secure that the instruments will not "feel" like a prototype afterwards. Naturally, also new developments are supported by a corresponding software. Take cantilever change as an example: For our DS 95 AFM, exchanging the cantilever takes only some seconds. Adjustment and approach are fully automatic, and optionally we also offer a full automatic cantilever changer. Furthermore, all our AFM scanners have a built-in optics facilitating the location of a specific place on the sample surface. Both guarantee efficient work and a high throughput.

Our instruments are characterized by an optimal combination of mechanics, electronics, and software. Only by in-depth harmonization of all three components, a good scanning probe microscope can be obtained. Our developers work interdisciplinarily: To make a good control software the developer must for example have also a deep understanding of mechanics and electronics. In the same manner, the mechanical development process must consider how the electronics and software will later control the system. Actually, the real power of our team of developers lies in the interdisciplinary work and the permanent overview of the whole concept.

All main parts of our Scanning Probe Microscopes are of our own manufacture; this includes the piezo motors for approach, the electronics, our software, and naturally our mechanical design. This has the advantage that we are able to quickly make modifications in all parts of the instruments, should a certain application require such.

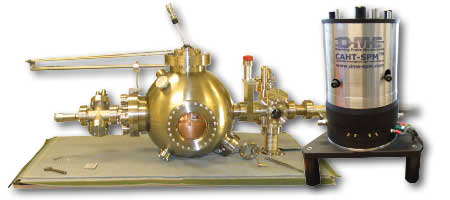

All of our products are individually configured to meet the customer requirements. The application is always in the foreground. We have a series of standard products that can be seen as a kind of starting point. If our product palette does not cover the application, we will modify the instrument, and not the application. In a complex area like nanotechnology this is quite often needed, otherwise the performance will be much lower than possible. Our experienced team can handle even the development of a fully new construction in accordance with the customer specifications. For special applications we are in close dialog with our customers to find the best solution and also how to realize it in the shortest possible time frame. Some examples of customer specified new constructions are the UHV-Raman-STM System, which includes a semi plane parabolic mirror as well as sample and tip exchange mechanisms, and a high temperature AFM (CAHT-AFM), which works at temperatures up to 800°C.

Would you like to try for yourself how it is to work with our instruments? Please contact us!